This family of furnaces includes continuous furnaces, in which the charge moves continuously from the inlet to the outlet, by means of an endless screw, or by tilting the oven. The retort acts as a muffle.

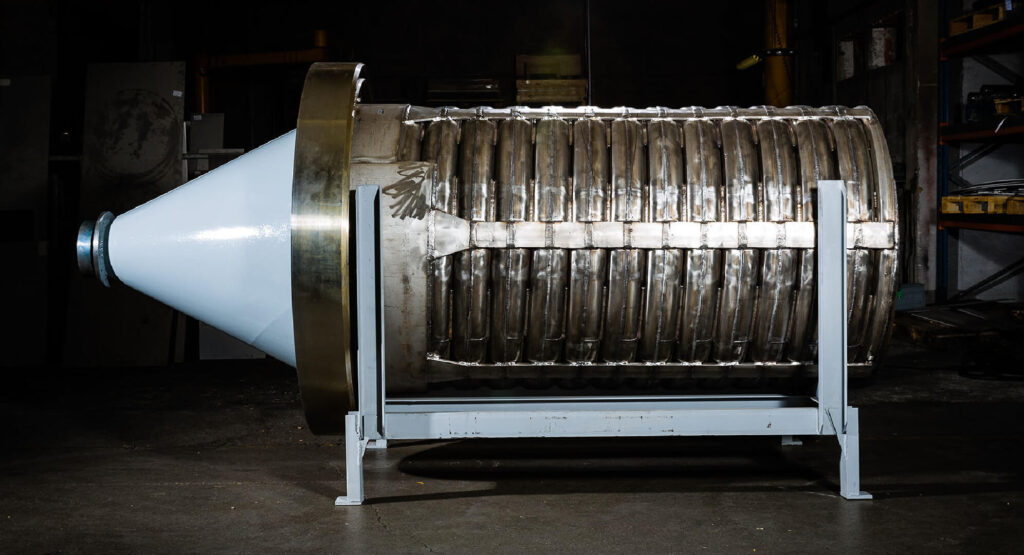

The retort

This is the major element of the furnace, confining the atmosphere and creating the transit movement of the parts, most often towards a quench. The alloy must be adapted to the type of treatment being carried out (case hardening, for example). The shape must be adapted to the size of the parts and to the operating mode of the furnace, and the manufacturing constraints often derive from this parameter.

We can offer you identical production of any type of retort for a rotary retort furnace, from the simplest to the most complex.

Our sales, technical and administrative teams are on hand to provide you with the rotary retort best suited to your real needs.

Rotary retort support

Located on the outside, it connects the rotary retort to the furnace drive system and can be made and adjusted during the manufacture of the retort. Although generally made of carbon steel, we can offer this type of part regardless of how it is produced (mechanically welded or cast).

Supply part

As some furnaces use a hopper or cone to feed the parts in, we can supply and fit this part to the retort and its support.

Other accessories

We have drawn on our years of experience and our knowledge of rotary retort furnaces and their environment to provide you with :

- The retort casing, which in some furnaces acts as an airtight enclosure.

- The retort plug.

And other accessories: retort shell closing plugs, tubes for temperature probes and gas injection.

RD Technologie is at your service for your parts: muffles, pits, bells, plugs, belts, soles, rails and furnaces accessories. Don’t hesitate to contact us for more information.